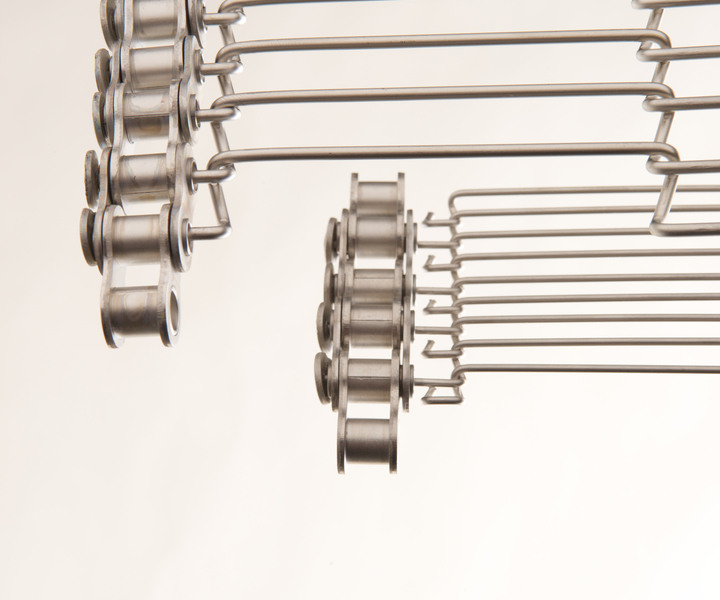

Rod Network Belt ECO

Rod Network Belt ECO

Rod network belts are characterized by their precise, maintenance-free belt run and small transfer radius. They are capable of reliably transporting even small products and seamlessly transferring them to downstream machines. The open mesh structure permits unobstructed, hygienic passage of liquids, heat, cold or air.

TOP-Characteristics

- Stainless steel versions approved for use in food processing per VO EC 1935/2004

- Economical solution for standard applications

- Positive guidance

- Small transfer radii

- Thin, flexible and light belt construction

- Permeable belt structure

- Hygienic design

Documents

- Rod Network Belt ECO Flyer

- Rod Network Belt ECO Endless Splicing Instructions

- Rod Network Belt ECO Manufacturing Tolerances

- Rod Network Belt ECO Technical Details

- Rod Network Belt ECO The Innovation K2390

- Rod Network Belt ECO with carriers

- Rod Network Belt ECO with guide chain

- Rod Network Belt ECO with points

Additional information

| Application Areas | Bread crumbing machines |

|---|---|

| Materials | 1.1211 spring steel wire 0.9-1.8(Used where no demands in terms of corrosion resistance) (Temperature range from -10° C to +70° C) |

| Dimensions | Up to 4000 mm wide, and above in special cases |

| Min Max Temp | -80 deg C |

| Speeds | Up to 15 m/min. |

| ACCESSORIES | Connection options |

| Can Be combined with | Carriers |