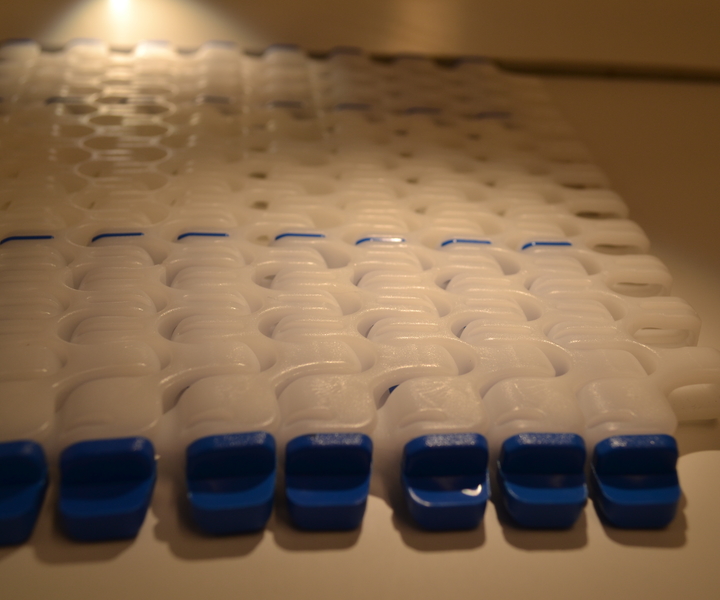

Plastic Modular Belt

Plastic Modular Belt

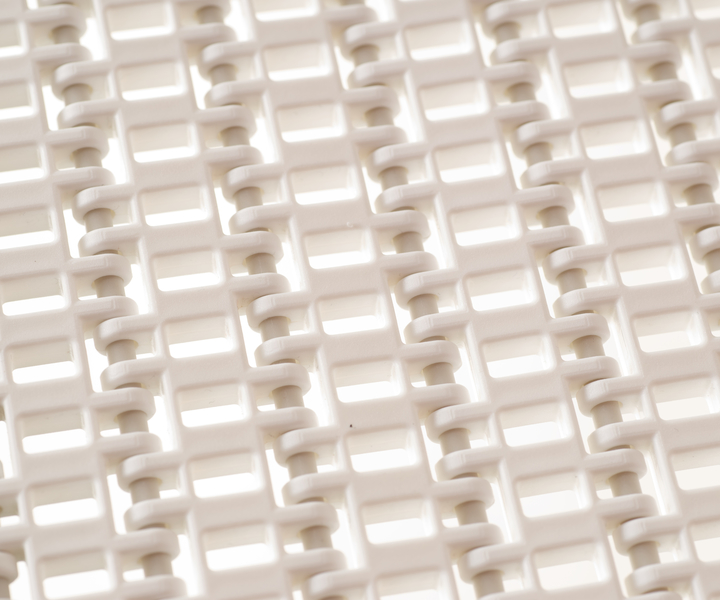

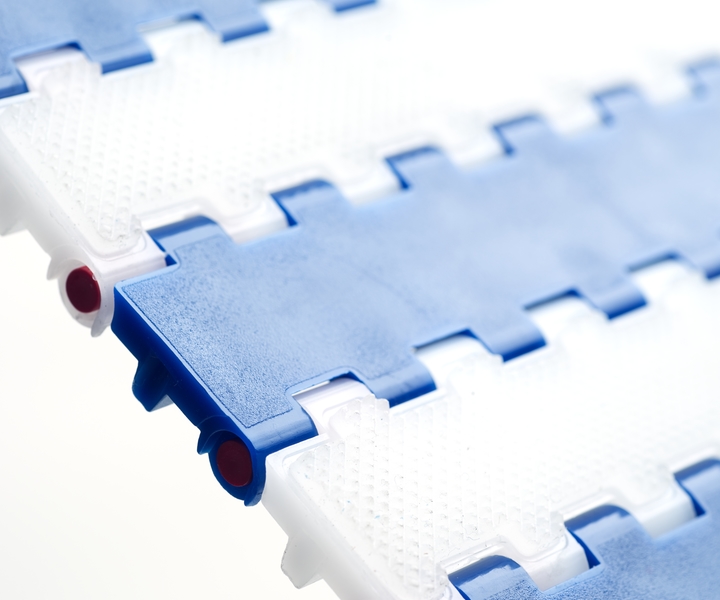

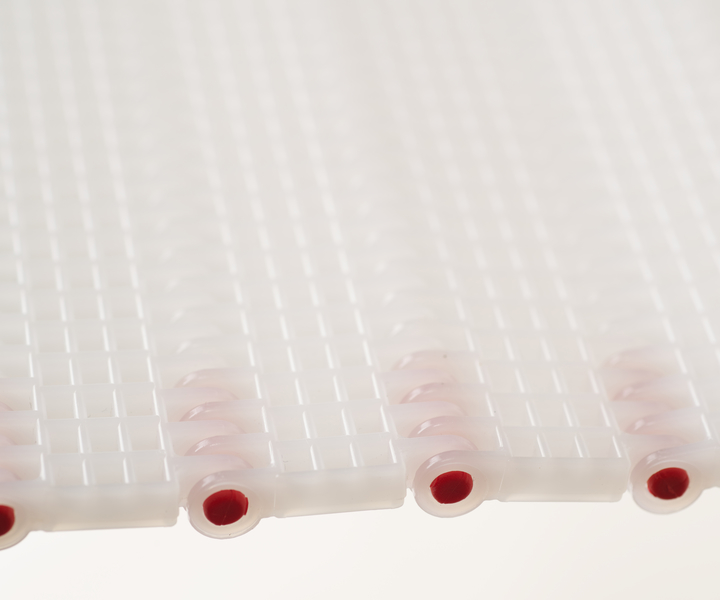

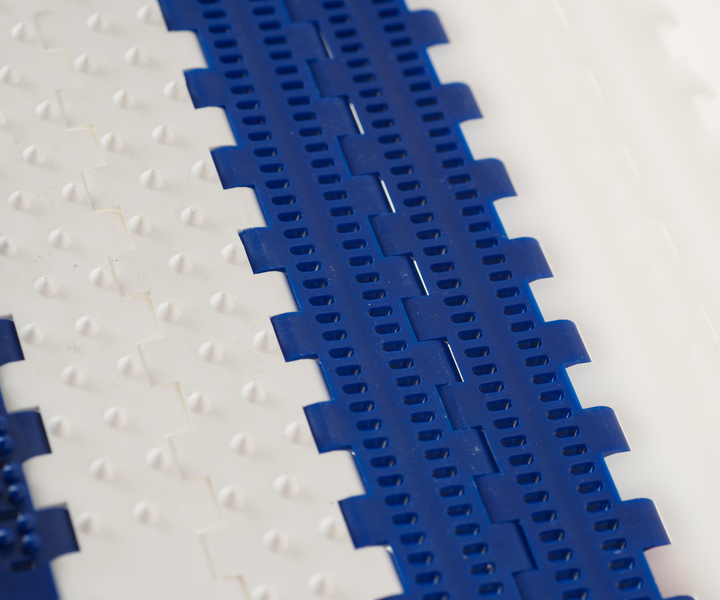

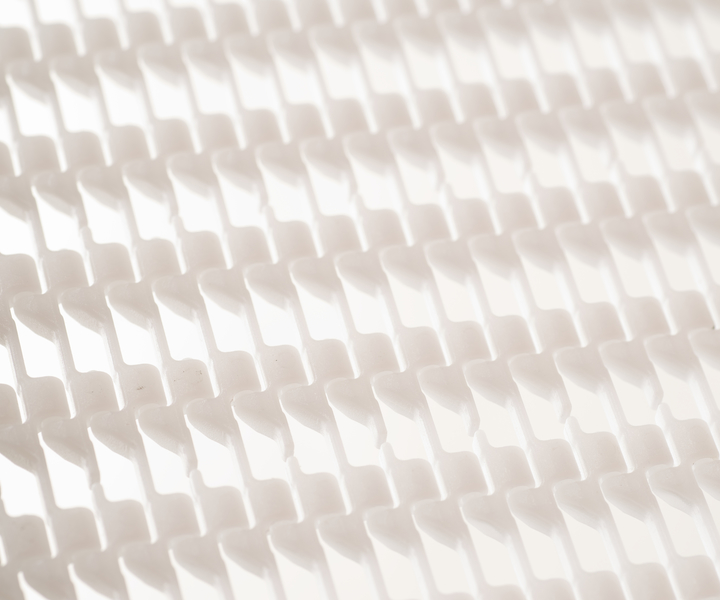

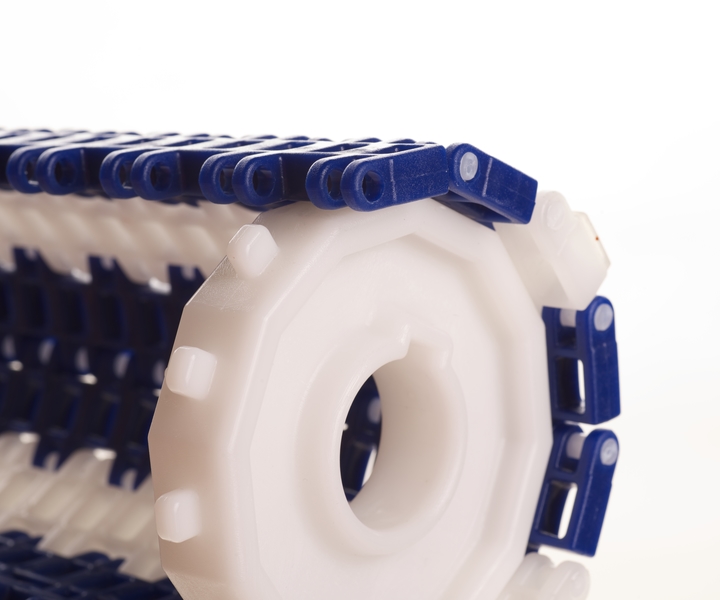

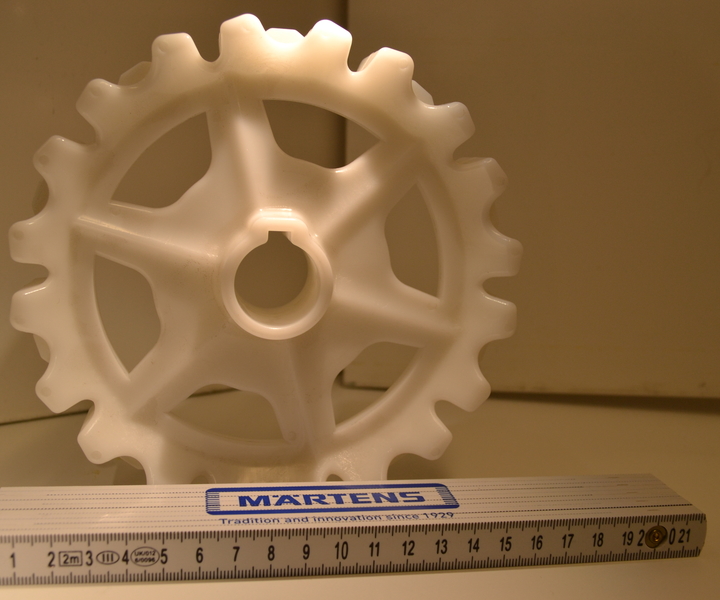

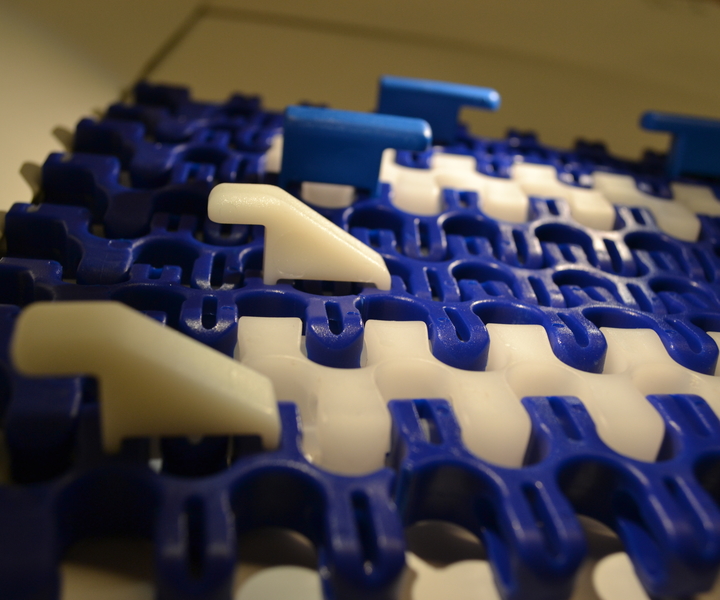

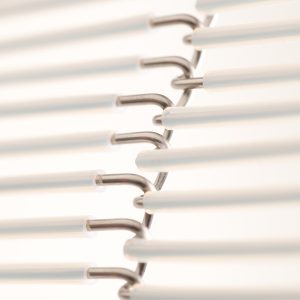

Low weight, high strength: Our modular conveyor belts are made of moulded plastic elements, which can be effortlessly connected in a variety of ways using bar joints. In addition to conventional versions in polyethylene, polypropylene or polyacetal, a range of special low-maintenance, stainless materials is also available.

Top Characteristics

- Durable and long-lasting

- Metric dimensions

- Versatile

- Hygienic design

- Simple connections

- Modular design

- Easy to clean

Documents

Description

Polyethylene (PE):

Elastic, impact-resistant, cold-resistant, this material is suitable for applications to -73° C. FDA approved for use in food processing.

Polypropylene (PP):

Neither aggressive substances nor temperatures up to +100° C can affect this material. FDA approved for use in food processing.

Polyacetal (POM):

This plastic is perfect for applications within a temperature zone of -43° C to +95° C with its high tensile force and low friction values. FDA approved for use in food processing.

Polyamid (PA):

Robust, pliable material with exceptional belt strength and a high level of notched impact strength. Temperature range from -45° C to +110° C

Additional information

| APPLICATION AREAS | Conveyor machines |

|---|---|

| MATERIALS | Polyacetal |

| SPECIAL VERSIONS | Anti-static version |